In my last post, I listed these items as my next steps:

1 Research 3D designers

2. Meet with each designer in person or via email

3. Send them my Afro Babies image and the specs and type of toy I have in mind

4. Work with the designer on getting the design correct and the colors of the outfits and phrase on the Afro Babies sign in place for mass customization

5. Send it off to Shapeways and other 3D manufacturers for a quote

6. Get the prototype made

7. Get the design photographed and begin to test its market viability

Prof. Zoe responded:

Your vision is great though I’m not sure it’s feasible to expect to make a product in such a short time. I’d break this down into something that you can actually accomplish. For instance, the first three steps seem like they could take you a long way toward your goal, and could be accomplished in the weeks ahead. perhaps you might add into that some research with other toy designers whose experience you might learn from, so that you don’t have to reinvent the wheel. Looking forward to seeing what you do.

As a result, this week I focused on steps 1 through 3. The following post outlines my process.

I sent emails to seven designers I found on the “3D Modelers for Hire” forum on Shapeways.com.

This is the email I sent:

I am trying to make a character. I have the image (It is attached).

I think the figure should be 3 inches tall and no more than 1 and 1/2 inches wide (at the base – the feet) would be the biggest.

Please tell me what is needed to give me a quote and estimated time to complete the design.

I am enrolled in a 3D printing class at Baruch College and this is a part of my project.

I sent my request to the designers who featured human faces and realistic characters in their portfolio. One of the persons I contacted was a man I met at the 3D Design Expo at the Javits center a few months ago. I talked with him when he was in the exhibit area holding several of his designs. I remember being intrigued by his “Success Kid“.

His name is Ryan Kittleson and his designs are incredible in details. He is especially adept at creating life-life faces. You can view more of his work here

The response I received from Ryan questioned how I wanted the flat sticker image taken into a 3D model. His reply: One concern is that it’s a very flat, graphic character, so there’s always some different ways of interpreting that in 3D. Depending on how particular you are about how it gets interpreted in 3D, the cost could be quite variable. If it takes a lot of back and forth between us to find the right 3D interpretation, it will cost more of course. However, if you don’t have a specific look in mind for how I sculpt it, I could get it done quite quickly and for not too much money (probably just about $200 on the low end)

Also, I heard back from Andrei Radu of BSK Designs team, Cheap 3D [email protected]. Our interactions were as follows:

Andrei: Does the model need to be flat with the outlines extruded?

Me: I need it to be a real “doll” type character. More like the way the attached character looks. Does that help?

Andrei: OK, for this kind of result we would need a front and a side view, similar to the one in our attachment.

Me: I do not have design skills and would need someone to make these sketches for me. I only have the sticker image that my friend’s husband (now deceased) drew.

Are you able to draw this or recommend someone I could work with?

Andrei: We are able to draw too, but just from the image you sent us, it is hard to guess the details as the image is something very flat and cartoonish, with almost no details to be interpreted.

Me: Do the images I sent of the toy figure help? Any suggestion on how I work with someone to explain how I need it to be drawn?

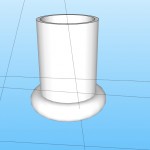

Below are the sketches he sent me to show the type of drawings he wanted me to supply. Beneath those are the images of a toy I sent him to show the type of body I am looking to have made. It is obvious that getting someone to take my flat sticker to a 3D image is a difficult design assignment.

The other designer who responded to me asked some very thoughtful questions that provided me with new langauge by which to express my needs. He replied:

Hello, I am Silvanus, 3D modeler from Shapeways forums.

I am pasting here the same text content of the PM I sent you in reply to your PM, at Shapeways. Just in case you preferred my answer being by email :

Hello.

I only have here one big doubt. You want the figure 1) as if it were a flat surface, kind of extruded flat silhouette, is it?

Or 2) Do you want actually a complete human figure, just stylized like it appears in that drawing, (with that graphical style) but having round section for arms, etc, I mean, being it a real figure with all volumetric, round surfaces? (a real human figure)

The first case would be the logical thing for an insignia. But I don’t know which is the purpose, please let me know if it is the first or second case..

If it is the first case, 60 $, and time frame: Right now is 23:27 in the night, here. So I’d make it during the day tomorrow, probably in my GMT +1 time, at lunch, or maybe along the afternoon – evening, as latest.

If it is the second case, 135$ and time to deliver, surely tomorrow night (in my GMT + 1 time)

Would you need it sooner?

In the case it is a flat silhouette (first case), just extruded after the more laborious work of tracing it, I need also to know if you want the internal black lines to be like carved or bumped instead. Consider we are doing this single color (ie, grey metal finish), and “black” is not seen as black. Unless you expect to print in the multicolor material -just consider that material is surely the most fragile of all. Ok only for decoration-

I can totally provide any model you wish be it the first or the second case. Just let me know if you would agree with these terms, and please clarify me if possible the questions I’m asking here, and then you will most probably have it by tomorrow.

Oh, I receive payments by Paypal, but can use a collection of other methods.

I responded:

I am looking to convert the flat image to a complete human figure with round section for arms. I do need a real figure with all volumetric, round surfaces. (a real human figure).

Please see the attached figures. I want it to look something like that about 3 inches tall and the feet about 1 inch long.

Does that help?

Notice my use of the term “volumetric.” I was happy to use the terms he had provided. It will help me shape my future communications with designers.

I have not heard back from Arthur Autz at the Zahn Center for Entrepreneurship @ City College. He was listed as a resource in Blackboard as one of the 3D printing options.

My preference now is to have Ryan make the model. I love his work and if he can take the Afro Babies from their current cartoonish look to a human cute kid faces, I would be very happy. I think he gets it. I might have Santiago do a design for me to to be able to compare their work. I might get Santiago to work on a different Afro Babies design.

Next week I think I will be able to focus on step 4: Work with the designer on getting the design correct and the colors of the outfits and phrase on the Afro Babies sign in place for mass customization.

I expect this to take a minimum of four weeks to accomplish. During this time, I am also researching other 3D manufacturing toy companies as Prof. Zoe suggested. In my next post, I will discuss my findings from that exploration.