A computer instructs the printer with a blue-print file in accordance with the desired cell type. The Organovo device consists of a stepper motor attatched to a robotic arm that orients the pump head, not at all dissimilar from the Makerbot in concept.

Two syringes are prepared. The first contains the cell-type that is the focus of the current procedure, lets say the parenchymal (functional) cells of the kidney nephron. They are usually contained in some kind of spheroid hydrogel encasing, making the entire medium look like an ink to the unaided human observer (thus the trade name BioInk). The second syringe is loaded with supplementary cell-types, structural cells, growth factors and what is known as a hydrogel. The first three components aid the growth and fusion process while the last provides a temporary 2-dimensional scaffolding.

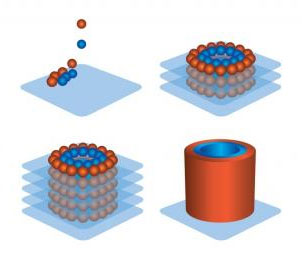

The second syringe begins printing a hexagonal or honeycomb-patterned layer of mold. A feedback loop forms between the immediately deposited material and a triangulation sensor; this orients the tip of the syringe in real-time. In other words, the sensor allows the device to correct-course throughout the entire process.

This is important because cells are alive. Recent dermal cell bio-printing demonstrations by Wake Forest university, where a live patient with 3rd degree burns had his skin directly printed onto a wound, showcase why it is important the BioPrinter be able to accommodate for uncertainty.

A layer of parenchymal cells is deposited. At this stage, the plate may be removed and incubated, or the process may be repeated until you have several, alternating layers of cells and hydro-gel mold on top of each other.

The hydro-gel dissolves as the the extracellular matrix and the distinct cells continues to fuse inside the incubator.