In spring 2021 a crisis hit my household: the filter stabilizers on my coffee maker cracked. While some might say, “no big deal, just get a new coffee maker” this was not possible as I had a Star Wars R2D2 french press. The company which made these glass and plastic treasures has since gone out of business, and I could not find a comparable piece of nerd art – even on the Internet.

Unfortunately, because of the questionable origins of the unofficially branded item, the filter stabilizers were also a little off when compared to a regular french press. The broken pieces were molded plastic, not the metal of a more quality (but less unique) press, so my theory was they were custom-made. This meant if I had some intact pieces I knew fit exactly I could send for some molded parts. And to get something exact, what I needed was a prototype.

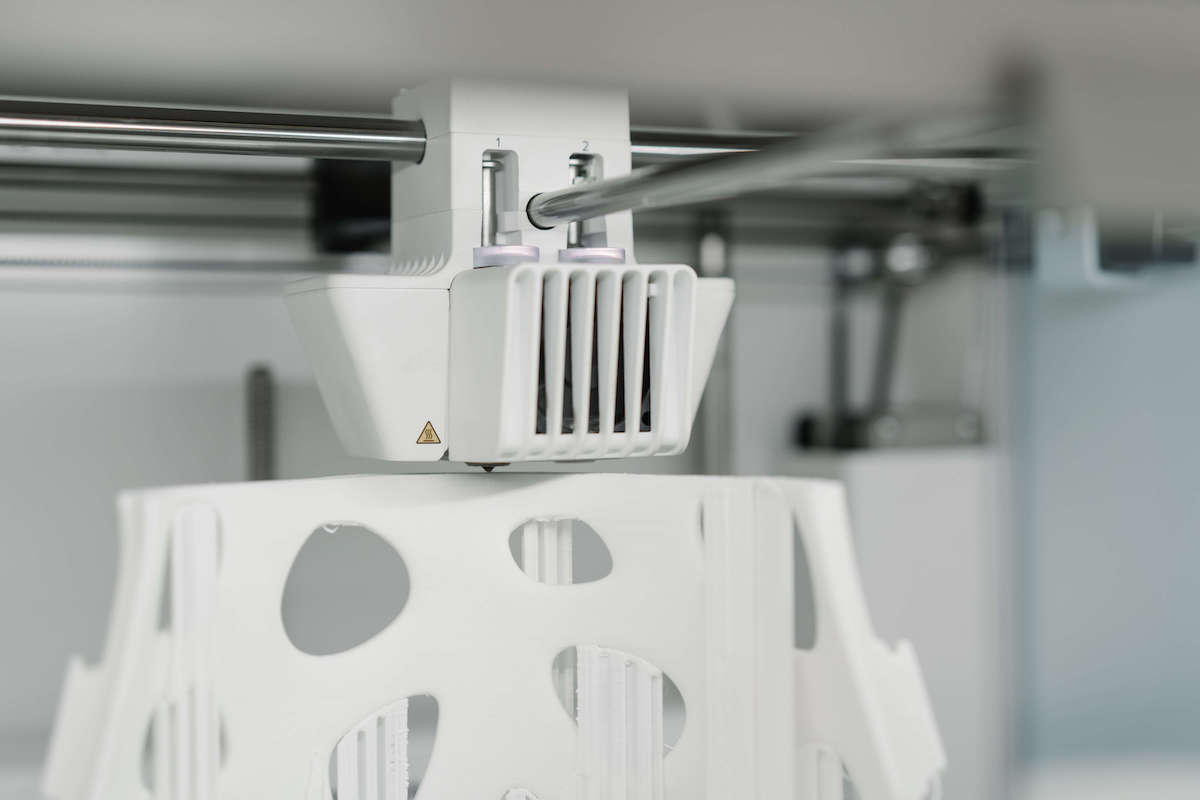

While I have a MakerBot Replicator 2x for creating a prototype, the compatible filament is ABS type. ABS has a high melting point and considered one of the stronger printing plastics, so printed materials could withstand boiling water without becoming deformed. It is also less porous than the most popular filament, PLA. However, ABS has several disadvantages: it is prone to warping without a heated printer base plate, releases fumes that can be hazardous when printed, and – importantly for my intended purpose – is not food safe.

In fact there are few filaments that are food-safe, most of them being expensive specialty plastics and all of them still with other considerations that would make it difficult to create parts for a french press. No matter the solution, I would likely have to coat the part in a durable and FDA-approved substance that would create a solid barrier and withstand near-boiling temperatures with repeated use.

Bars, counters, and some tables are coated in resin – a plant-based or synthetic and organic blended sap that solidifies into a hard, clear substance. If mixed properly, it creates a barrier between a porous material such as wood or plastic and food. Most commercial plant versions and some synthetics – if properly mixed and applied – are FDA approved, and have high heat resistance. No matter the print material beyond the prototype, I would still need to account for the coating thickness.

Measuring when you are accounting for a coating beyond the print is more than taking a little off the sides. The metal push rod still has to be able to pass through the wire mesh filter, and the stabilizing pieces holding the filter in place are held in place on the push rod using threaded nuts. In order to properly fit all of the pieces and make it safe to use, each piece would need a proper thickness coat and be affixed without gaps or holes.

This is why we prototype: it is not just for creating a new product sample or a scale model. Proper prototyping can be used as a way to make objects safer, to check measurements with the right additional elements, and to make sure you have thought of everything ahead of investing in and sending away for a print with harder materials or even in a molded metal or ceramic casting.

We will look more at different materials, different printers, and other options for advanced printing in this short series on 3D prototyping with safety and purpose in mind. First we will measure, model, and export the piece. Then we will look at some filaments and printers you might use for different purposes, and briefly discuss more about accounting for coatings. Finally, we will examine a few options for sending away for a final print if it is not something you could do at home or school.

And please remember: this is about a prototype. Do not use uncoated, home-printed, non-FDA approved material prints with food – even if it is intended to be in limited contact with the food or the person, like a plate.